News

GRX Multi-Jaw Demolition Tool Wins World Demolition Award

The Genesis GRX Razer X Multi-Jaw Demolition Tool has received…

Cost-effective demolition of viaducts

Demolition shears as the key equipment The Langenschwarz Viaduct on…

SUCCESSFUL TOGETHER

GENESIS and NPK together at bauma 2022

For the first time GENESIS GmbH presented hydraulic attachments together with NPK Europe on a stand of almost 600 sqm at this year’s bauma in Munich.

NPK, one of the world’s largest manufacturers of hydraulic attachments for all types of carriers, gave an impressive insight into the NPK product groups for the demolition and construction industry. Among others, ham-mers, crushers, pulverizers and grabs for demolition work in different dimensions were presented.

According to the GENESIS motto “Promise of Performance”, our entire product range of high-quality and absolutely reliable hydraulic attach-ments especially for scrap, demolition and recycling was of course also presented to the trade visitors and customers.

Powerhouse in focus

The focus at the world’s leading trade fair for construction machinery was on the impressive, 5-meter-long GENESIS XT 995 scrap shear with a total weight of 8.9 tons. Due to the outstanding power to weight ratio, the GXT 995R is a real powerhouse and a perfect fit for various applications from ship wrecking, large steel demolition projects and scrap processing.

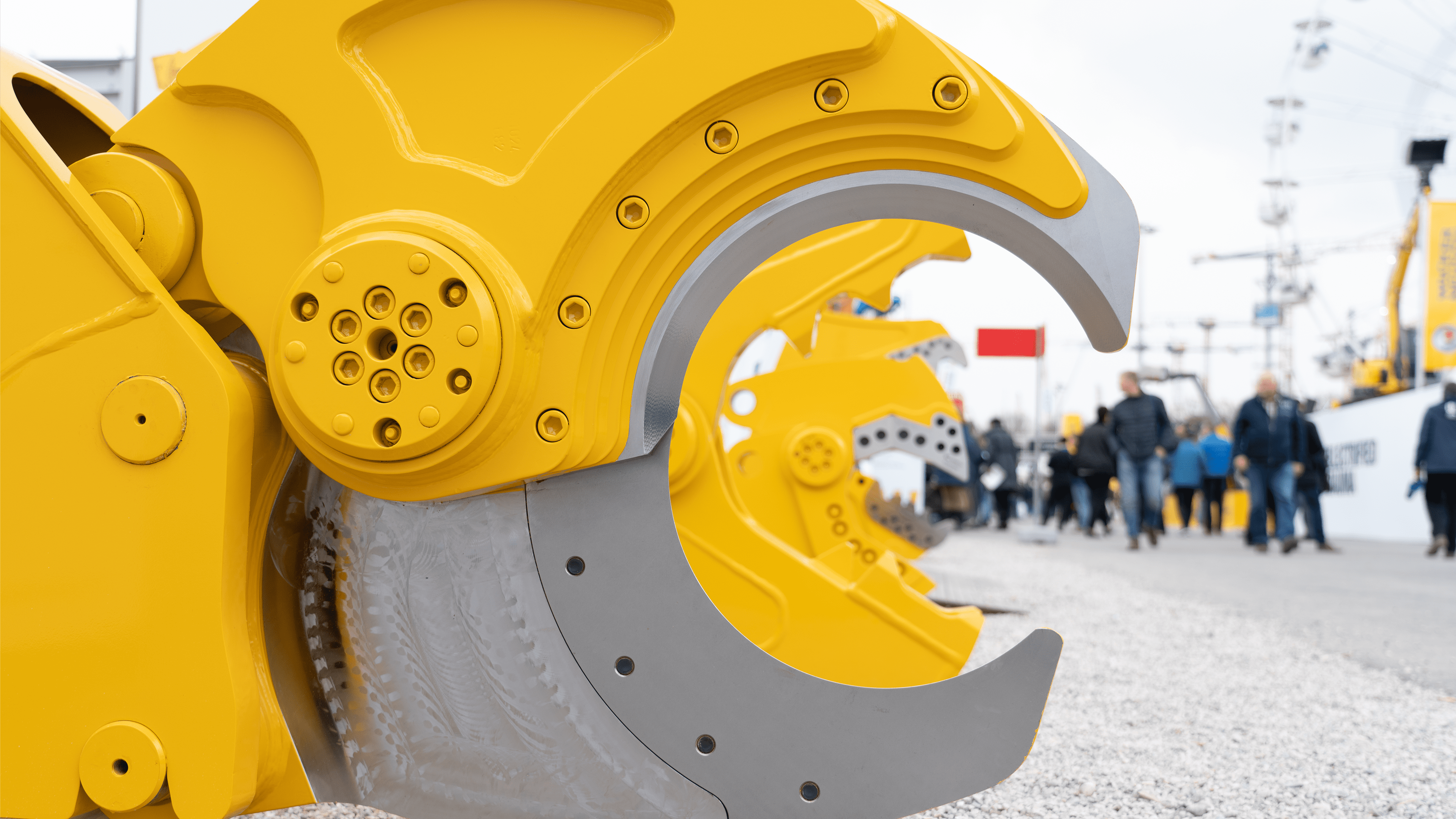

Demolition and demolition multishear

This was flanked by various models of the GENESIS GDT demolition shear and the latest model in the GENESIS family, the GENESIS Razer X demo-lition multishear.

The Razer X demolition multi-shears are tailormade for the demolition and recycling industries and their special requirements. The multi-talents have three jaw sets that can be changed in less than two minutes – without assistance and without the excavator operator having to leave his cab. The user-friendly multi-shears are available for excavators from 20 to 50t.

Graffiti Live Performance

Environmental protection and emission reduction

Our ArtShear also conveys the ecological aspect particularly clearly. The use of our scrap shears saves emissions and CO2 and is a clean alternative to flame cutting. GENESIS scrap shears are therefore not only ecologically advantageous – they are also streets ahead in terms of economic effi-ciency.

When “cutting instead of burning” is chosen, this not least also protects the employees, because the emissions produced during cutting do not only harm the environment, but also endanger health.